Tevo Tarantula: Top 7 Upgrades for Incredible Prints

The Tevo Tarantula is a popular and affordable 3D printer, known for its large build volume and ease of use. However, like any entry-level machine, it can be significantly improved with strategic upgrades. This guide will explore seven essential upgrades to transform your Tevo Tarantula into a high-performance 3D printing powerhouse. These upgrades focus on improving print quality, reliability, and overall user experience. Whether you’re a beginner or an experienced maker, these enhancements will help you achieve superior prints and unlock the full potential of your Tevo Tarantula. Let’s dive into the world of upgrades and discover how to take your 3D printing projects to the next level. By implementing these modifications, you can expect to see a marked improvement in the precision, durability, and aesthetic quality of your 3D printed objects. It’s about optimizing every aspect of your printer for exceptional results.

Upgrading the Bed

A stable and level bed is the foundation of every successful 3D print. The original Tevo Tarantula bed can be improved for better adhesion and flatness. Upgrading the bed surface and ensuring accurate leveling are crucial steps towards achieving high-quality prints. This upgrade focuses on creating a more reliable printing surface and simplifying the bed leveling process. This ensures the first layer adheres correctly, which is critical for the overall success of the print. A well-prepared bed reduces warping, improves dimensional accuracy, and minimizes print failures, ultimately saving time and material. The right bed upgrade and leveling process can make a significant difference in your printing experience. Remember, a perfectly leveled bed allows for the first layer to stick without the nozzle touching the bed.

Glass Bed vs. PEI Sheet

Consider replacing the original bed with a glass bed or a PEI (Polyetherimide) sheet. A glass bed offers a smooth, flat surface and is generally easy to clean, but may require adhesive for some materials. PEI sheets, on the other hand, provide excellent adhesion and are known for their durability and ease of use; prints often release cleanly when the bed cools. Both are superior to the original bed surface in terms of flatness and print adhesion. A glass bed is cost-effective and improves surface finish, while PEI provides superior adhesion for various filaments, including ABS and PETG. Both upgrades help to prevent warping and improve the quality of the first layer, directly impacting the final print quality. Choosing the best option comes down to personal preference and the types of filaments you use most often.

Leveling the Bed Accurately

Precise bed leveling is non-negotiable. While the Tevo Tarantula has manual bed leveling, consider adding auto-bed leveling (ABL) for convenience and accuracy. Whether manual or automated, ensure the bed is perfectly level before each print. Use a leveling probe or the paper method to calibrate the nozzle’s height above the bed. The ABL systems utilize sensors to map the bed’s surface and compensate for any imperfections, resulting in a consistent first layer. Regular bed leveling, especially after changing nozzles or removing prints, is essential for consistently good prints. A well-leveled bed guarantees the first layer adheres correctly, preventing warping and improving overall print quality. Proper bed leveling can significantly reduce print failures and improve print quality.

Improving the Extruder

The extruder is responsible for pushing filament into the hotend. Upgrading the extruder can greatly enhance print quality and reliability. Improved extrusion control leads to more precise material deposition, reducing issues such as under-extrusion and over-extrusion. The upgraded extruder will provide more consistent filament flow to the hotend. Improving the extruder allows you to print a wider range of filaments, including more demanding materials like flexible filaments. This part of the printer is essential for optimal print quality. By doing this, you are also improving speed and overall better prints. This upgrade can drastically impact your print quality.

Metal Extruder Upgrade

Replace the stock plastic extruder with a metal version. Metal extruders are more durable and provide better grip on the filament. They also allow for higher extrusion forces, which is particularly useful when printing at faster speeds or with stiffer filaments. Metal extruders reduce the risk of cracking, a common issue with the original plastic components. Improved grip prevents filament slippage, ensuring a consistent flow of material. This results in more precise extrusion, leading to improved print quality and reduced print failures. The enhanced durability also extends the extruder’s lifespan. This means you have fewer maintenance needs for the extruder.

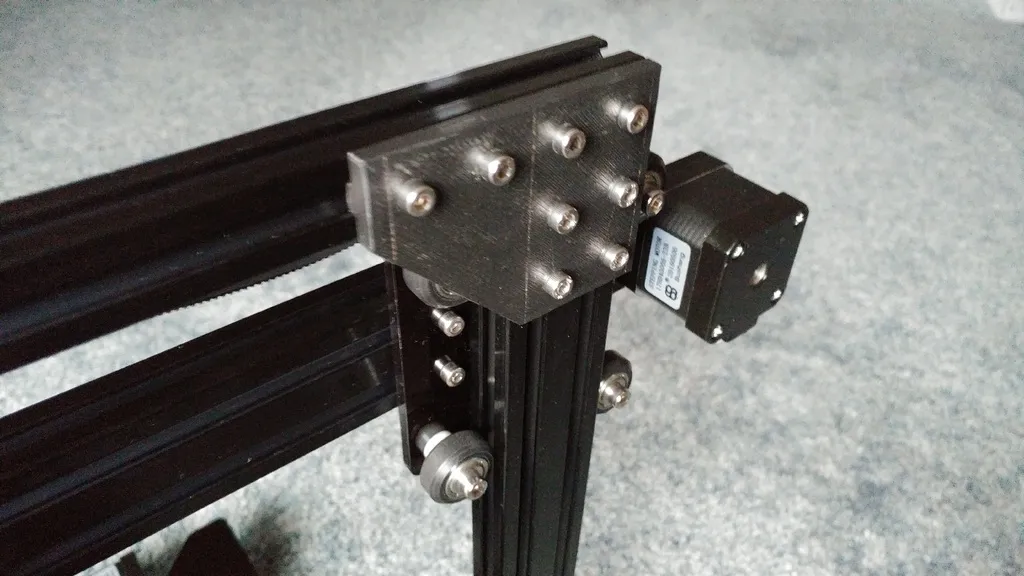

Direct Drive Extruder Conversion

Consider a direct drive extruder conversion. This moves the extruder motor directly above the hotend, reducing the distance the filament needs to travel. This improves retraction performance, reduces stringing, and enhances the printer’s ability to handle flexible filaments. Direct drive setups offer better control over filament flow, resulting in sharper details and higher print accuracy. This setup minimizes the amount of distance the filament has to travel. This means that the printer has more control over the entire process. This improves print quality overall and allows for better print control. This is a great upgrade for fine details and flexible filament.

Enhancing the Hotend

The hotend is the part of the 3D printer that melts the filament. Upgrading the hotend can significantly improve your print quality by allowing higher printing temperatures and enhanced control over the melting process. The improvements lead to better print precision and the ability to print with a wider range of filaments. Enhancements allow you to print with various filaments that require higher temperatures, resulting in more versatility. It ensures that the melted filament is correctly delivered and prepared for extrusion. Proper hotend maintenance is vital for excellent print quality and reliability. Remember that you are enhancing the melting, and control process for the filament.

All-Metal Hotend for Higher Temperatures

Install an all-metal hotend to enable higher printing temperatures. This upgrade is essential for printing materials like ABS, nylon, and polycarbonate. All-metal hotends can withstand higher temperatures without degradation, expanding the range of filaments you can use. They also improve the overall printing performance, providing better heat distribution and melting efficiency. With this you will not only be able to print at higher temperatures but have more control and better overall performance. This is an excellent option for high-temperature filaments. This also reduces the chance of clogs.

Nozzle Upgrades for Print Quality

Experiment with different nozzle sizes and materials. Stainless steel nozzles are more durable than brass and are better suited for abrasive filaments. Different nozzle sizes allow for varying levels of detail and print speeds. A smaller nozzle will provide finer detail, while a larger one will allow for faster prints. Ensure the nozzle is properly tightened to prevent leaks. Selecting the right nozzle can greatly improve your print quality and reduce the wear and tear on your 3D printer. Choosing the right nozzle for your needs helps to improve print quality. This can also help reduce printing failures. Always be sure to tighten your nozzle.

Optimizing the Frame

A stable frame is crucial for print accuracy. The Tevo Tarantula’s frame can be improved with modifications to enhance stability and reduce vibrations. Frame stability reduces the possibility of print artifacts, which affects the overall quality. Optimizing the frame also contributes to reducing noise and improving the reliability of your prints. The Tevo Tarantula frame can be improved, which will reduce the possibility of errors or artifacts, and help create better overall prints.

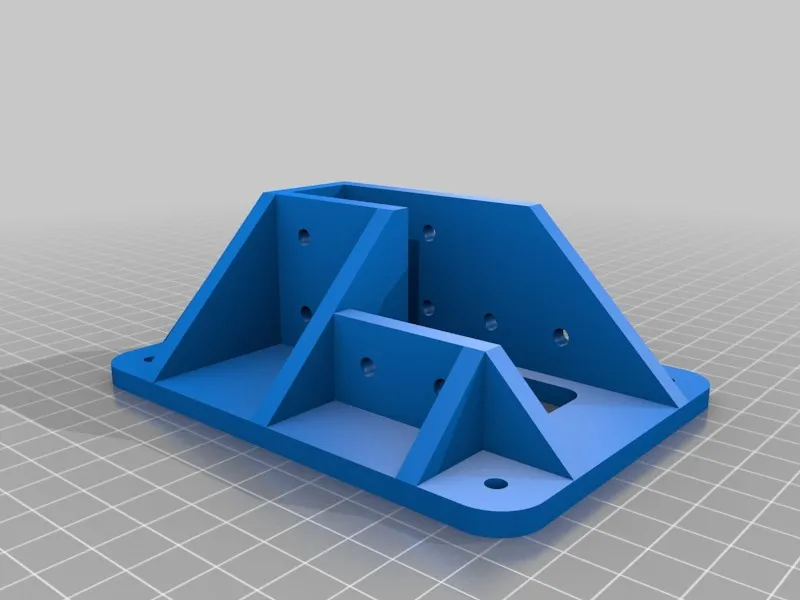

Reinforcing the Z-Axis

Reinforce the Z-axis with additional supports or brackets to minimize wobble and improve layer alignment. A stable Z-axis is vital for consistent layer heights. Adding support reduces the risk of layer shifting and improves the overall quality of your prints, especially on taller objects. Z-axis stability helps ensure consistent layer alignment and prevents unwanted artifacts. By strengthening the Z-axis, you’ll achieve higher print accuracy. Adding extra support reduces movement and is a great investment. This will also help with prints that have a taller height.

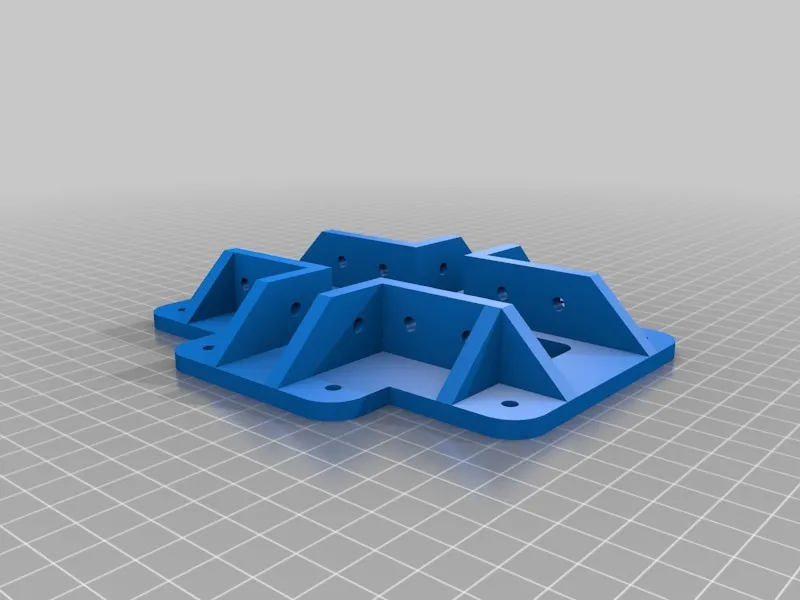

Adding Braces for Stability

Add corner braces or other structural supports to the frame to reduce flex and vibrations during printing. Stiffening the frame helps reduce ringing and other print artifacts. These braces improve overall print quality and dimensional accuracy. These additions help to minimize movement and vibrations in the frame. This will lead to better print results. Reduce any vibrations in the frame and make for better quality prints. This is a great addition for all printers.

Upgrading the Electronics

Upgrading the electronics can enhance the performance and usability of your Tevo Tarantula. Better electronics will provide smoother and quieter operation, and improve overall print quality. The right upgrades can extend the life of your printer and give you more control over the printing process. By optimizing the electronics, you’ll get better prints overall. With the right modifications, you can improve printing speeds. The correct upgrades can lead to many benefits.

Silent Stepper Drivers

Replace the stock stepper motor drivers with silent ones, like the TMC2208 or TMC2209. These drivers significantly reduce the noise produced by the printer, making for a quieter printing experience. Silent stepper drivers also contribute to smoother motor movements, which can improve print quality by reducing vibrations. This improves the user experience by making the printer quieter. These drivers will improve print quality by reducing vibrations. You will enjoy the silence that comes with silent stepper drivers.

Upgrading the Mainboard

Consider upgrading the mainboard for improved features and performance. A modern mainboard can offer better processing power, expanded memory, and support for advanced features like auto-bed leveling and Wi-Fi connectivity. Make sure the new board is compatible with the Tevo Tarantula and that it is able to provide better features. With the right upgrades, you’ll have more control over the 3D printing process. The board upgrades the printer and provides better features. This upgrade is a great option for those looking to expand their printers abilities.

Enhancing the Cooling System

Effective cooling is essential for high-quality prints. Improving the cooling system on your Tevo Tarantula can enhance print resolution, reduce warping, and improve overhang performance. Enhancing the cooling system ensures better print quality. Proper cooling also reduces the likelihood of print defects, improving the overall results. Better cooling allows for better control of the printed material. Improve your prints by cooling the material.

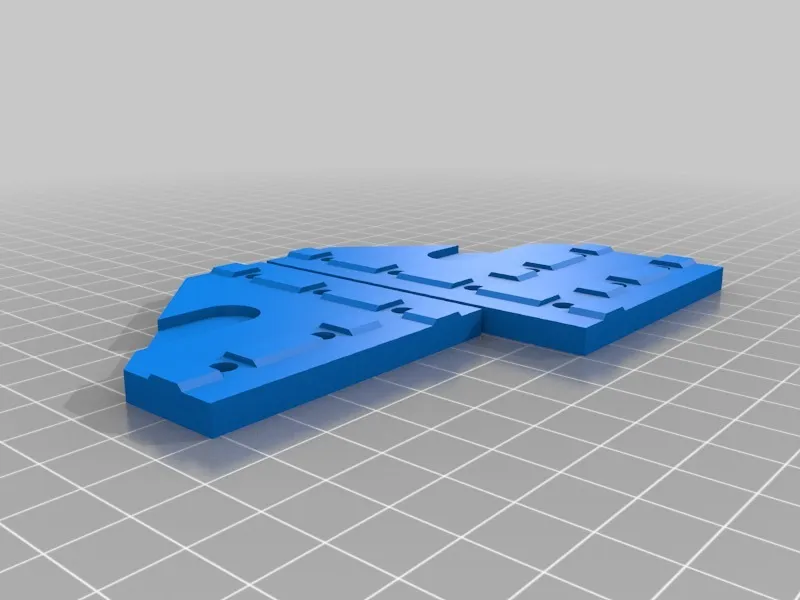

Fan Duct Design for Better Cooling

Replace the stock fan duct with a more efficient design. An improved fan duct can direct airflow more precisely onto the printed part, enhancing cooling efficiency and improving overhangs and bridging performance. Well-designed fan ducts provide better airflow. Better cooling improves the ability of a printer to handle overhanging. You can choose from various designs and materials for the perfect duct. An effective fan duct will provide more efficient cooling, which results in higher-quality prints. Improving cooling is essential for quality.

Upgrading the Power Supply

A reliable power supply is critical for consistent print quality. Upgrading the power supply can improve your printer’s reliability and reduce the risk of print failures. The best power supply should provide adequate power for all components. This will improve print quality and reduce failures. A well-chosen power supply will help avoid issues and ensure your printer runs smoothly. You want to make sure your power supply meets all power requirements.

Reliable Power Supply for Consistent Prints

Replace the stock power supply with a higher-quality unit, especially if you plan on adding power-hungry upgrades. This will ensure a stable power supply and prevent voltage fluctuations that could interrupt prints. A reliable power supply will ensure that all components receive the power they need. This will help prevent failed prints and extend the lifespan of your 3D printer. Select a power supply with enough capacity to handle any future upgrades you may add. This guarantees a steady flow of power to all the components. Make sure the power supply can handle the printer’s needs.

In conclusion, upgrading your Tevo Tarantula with these seven essential modifications can significantly enhance your 3D printing experience. From bed leveling and extruder improvements to frame reinforcement and electronics upgrades, each enhancement contributes to better print quality, increased reliability, and overall usability. By taking the time to implement these upgrades, you will unlock the full potential of your Tevo Tarantula. Remember to research each upgrade thoroughly, choose high-quality components, and follow instructions carefully for the best results. Embrace the DIY spirit and transform your printer into a high-performance machine, ready to tackle any 3D printing project with confidence. The result is a printer that is both powerful and dependable, delivering incredible prints every time. With these upgrades, you can enjoy a greatly improved 3D printing experience.