Upgrading Your Tevo Tarantula: Top 7 Tips

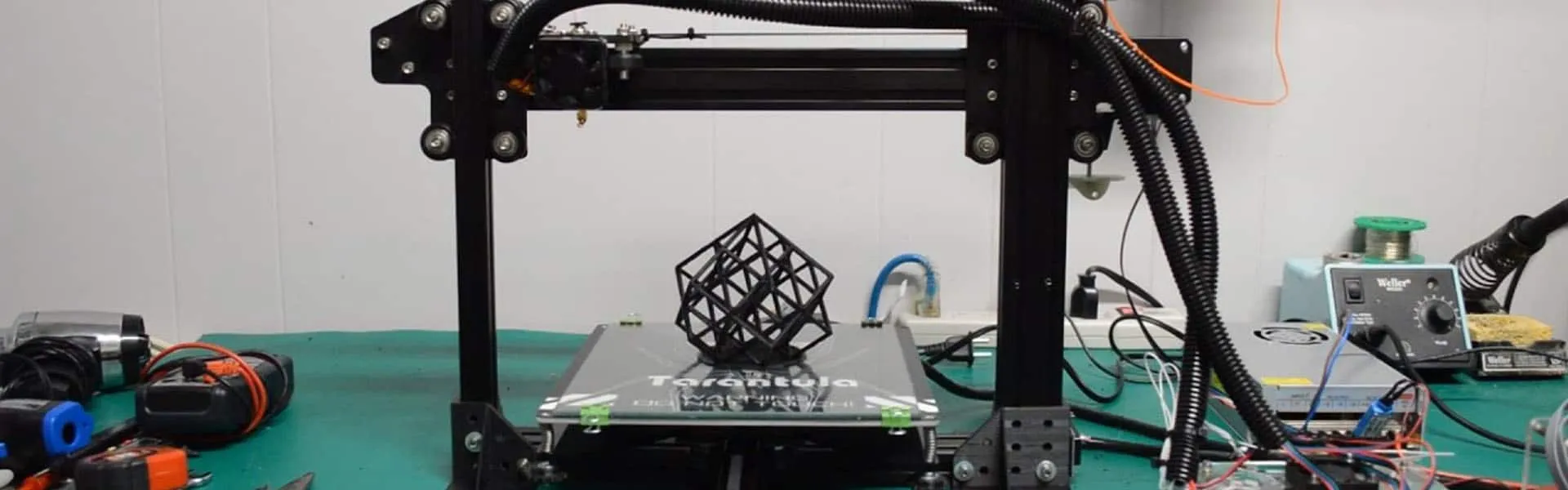

The Tevo Tarantula 3D printer is a popular choice for hobbyists and beginners due to its affordability and open-source design. However, like any entry-level 3D printer, the Tevo Tarantula can benefit significantly from upgrades. These enhancements can improve print quality, reliability, and overall user experience. This guide offers seven essential upgrade tips to elevate your Tevo Tarantula from a good printer to a great one. Whether you are looking to improve print speed, accuracy, or ease of use, these upgrades will help you achieve your 3D printing goals. Remember to always prioritize safety and consult online resources for detailed installation instructions before making any modifications to your printer. With the right upgrades, your Tevo Tarantula can produce professional-quality prints and become a reliable part of your creative toolkit. The upgrades are broken down into different categories so you can pick and choose what best suits your needs and budget.

Choosing the Right Upgrades

Before diving into specific upgrades, it’s crucial to assess your needs and understand what improvements are most important to you. Consider what aspects of your prints you’re not satisfied with, whether it’s layer adhesion, print speed, or ease of use. Researching common issues and limitations of the Tevo Tarantula, such as potential issues with the stock extruder or bed leveling, will also help you prioritize. Take into account your budget and the time you’re willing to invest in the upgrades. Some upgrades, like installing a new hotend, can be more complex than others, like replacing the fan. Start with the upgrades that address your most significant pain points and gradually improve your printer. Also consider that some upgrades may require others to fully realize their potential, so think about the overall system and how the upgrades interact with each other. Careful planning and a clear understanding of your goals will ensure that your upgrade journey is both effective and enjoyable.

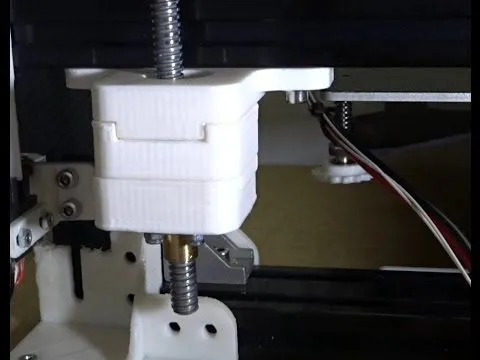

Extruder Upgrades

The extruder is a critical component responsible for feeding filament into the hotend. Upgrading the extruder can lead to more consistent and reliable filament feeding, resulting in improved print quality. The stock extruder on the Tevo Tarantula is often a weak point, and upgrading to a metal extruder is a common and highly recommended modification. A metal extruder provides better grip on the filament and reduces the chances of filament grinding or slipping. This upgrade can lead to better control over the filament flow and more accurate prints. When choosing an extruder upgrade, ensure that it is compatible with the Tevo Tarantula and that you have the necessary tools for installation. Carefully follow the installation instructions and calibrate the extruder properly after installation to ensure that it feeds the filament at the correct rate. Extruder upgrades can also improve the printer’s ability to handle a wider variety of filaments, including flexible and abrasive materials.

Metal Extruder Benefits

Metal extruders offer several advantages over the stock plastic extruder. They are more durable and less prone to wear and tear. The increased rigidity of a metal extruder provides better control over filament feeding, minimizing the risk of filament grinding. The improved grip of the metal extruder significantly reduces the likelihood of filament slipping, leading to more consistent extrusion and improved print quality, particularly for demanding filaments. Metal extruders usually include adjustable tension mechanisms that allow for fine-tuning of the filament grip. This fine-tuning is particularly helpful for achieving the correct pressure on the filament without damaging it. The increased reliability of a metal extruder means fewer print failures due to extrusion problems and more time spent printing successfully. Consider the benefits of metal extruders a worthwhile investment in the overall performance of your Tevo Tarantula.

Hotend Upgrades for Better Performance

The hotend is responsible for melting the filament and extruding it onto the print bed. Upgrading the hotend can enhance printing performance and provide better temperature control. A common upgrade is replacing the stock hotend with an all-metal hotend. All-metal hotends are capable of reaching higher temperatures, allowing you to print with a wider range of filaments, including high-temperature materials like polycarbonate and nylon. When choosing a hotend upgrade, consider factors such as the compatibility with the Tevo Tarantula, the ease of installation, and the temperature range. Ensure you have the necessary thermal management solutions to maintain stable temperatures during printing. This upgrade will allow you to unlock the full potential of your 3D printer, giving you the ability to explore new materials and print with greater precision and speed. Proper calibration of the hotend temperature settings is crucial for achieving optimal print results.

All-Metal Hotend Advantages

All-metal hotends have significant advantages over stock hotends, especially for more advanced 3D printing. They are designed to handle higher temperatures, enabling the printing of materials that require higher melting points. This opens up a new world of possibilities in terms of materials and applications. All-metal hotends are often more durable and have a longer lifespan compared to hotends with PTFE liners. The absence of a PTFE tube inside the hotend can also reduce the risk of material degradation at high temperatures. This design feature enhances the overall reliability of the printing process. By minimizing the chance of clogs and ensuring smoother filament flow, all-metal hotends improve print quality and reduce the likelihood of printing errors. If you want to work with more advanced and challenging filaments, an all-metal hotend upgrade is highly recommended.

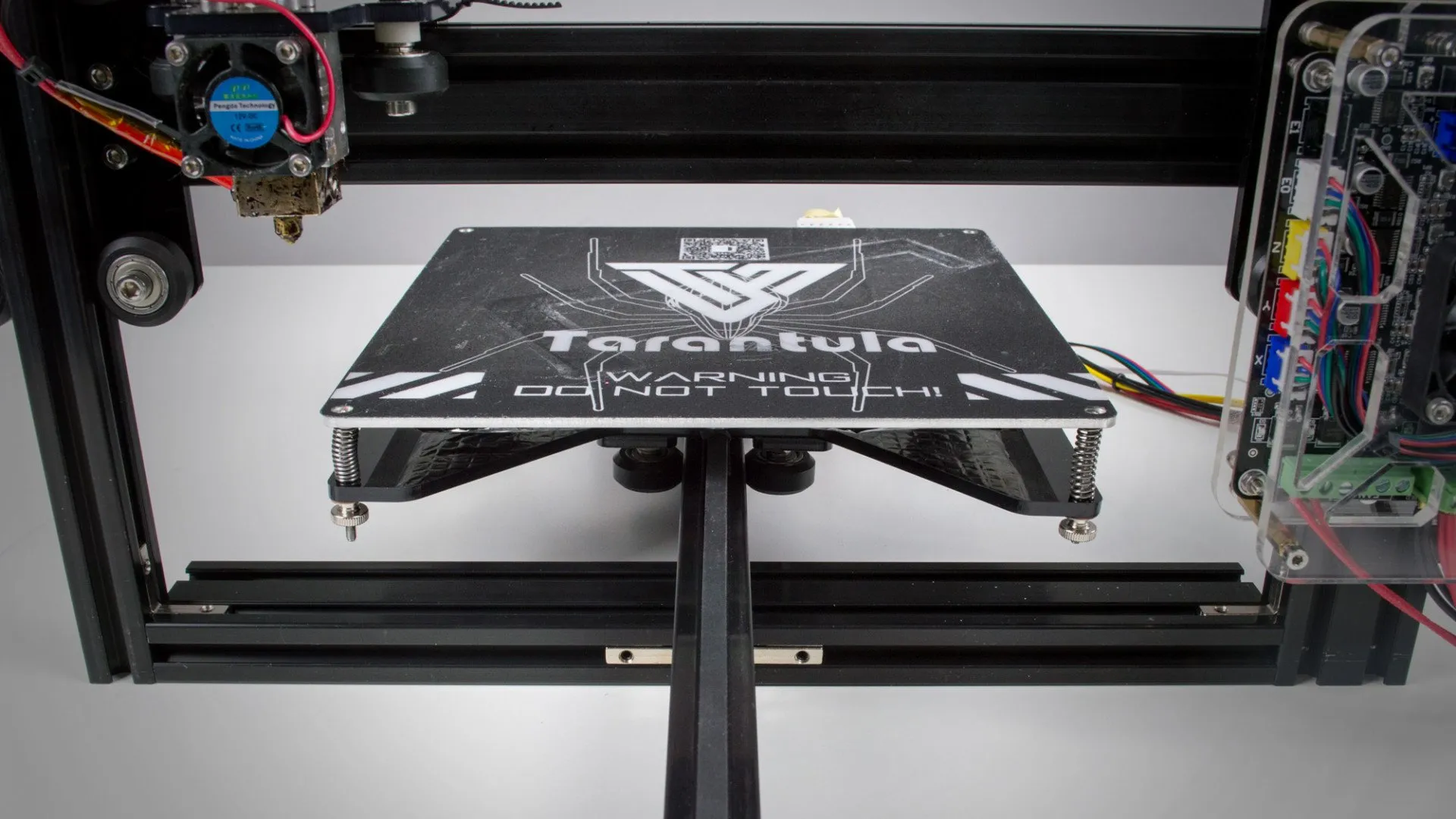

Bed Leveling Upgrades

Bed leveling is crucial for the first layer adhesion, which directly impacts the quality of the entire print. Manual bed leveling can be time-consuming and requires frequent adjustments. Upgrading to an automatic bed leveling (ABL) system simplifies this process and increases print success rates. ABL systems use sensors to measure the distance between the nozzle and the print bed and adjust the Z-axis accordingly. This ensures a consistent first layer, even if the bed is slightly warped. Choosing an ABL system depends on your preferences and budget. Popular options include inductive sensors, capacitive sensors, and the BLTouch sensor. These systems automate the bed leveling process and significantly improve the ease of use of the printer. Carefully follow installation instructions and calibrate the ABL system to ensure accurate and reliable bed leveling. The consistency of the first layer creates the foundation for the rest of your print, thereby increasing your odds of success.

Automatic Bed Leveling Options

Automatic bed leveling options offer significant convenience and improved print quality compared to manual leveling. Inductive sensors are a popular option, as they detect the presence of a metallic bed. They are reliable and easy to install, though they require a metal print bed. Capacitive sensors can be used with various bed types, including glass and plastic, but they can be more sensitive to environmental factors. The BLTouch is another popular choice; it is a highly regarded and accurate sensor that probes the bed and creates a mesh. All automatic bed leveling systems require firmware configuration. Ensure you research and follow the appropriate configuration instructions for your specific ABL sensor and printer. ABL upgrades can significantly reduce the time spent on bed leveling and improve the success rate of your prints. This means more time printing and less time troubleshooting. These automatic systems are a valuable addition to any Tevo Tarantula.

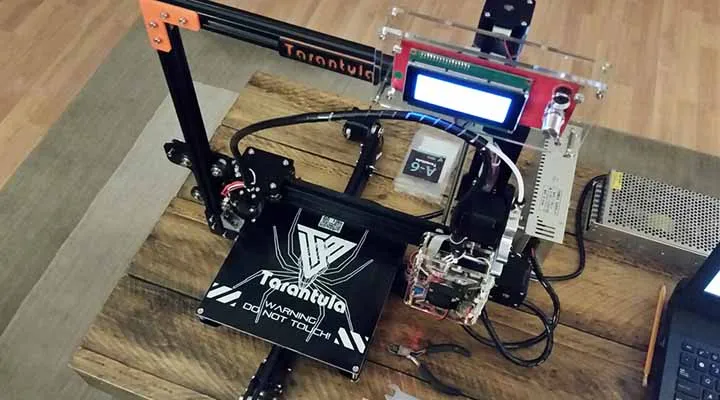

Firmware and Control Board Upgrades

The firmware and control board are the brains of your 3D printer, and upgrading these components can unlock advanced features and improve performance. Upgrading the firmware to Marlin or Klipper firmware provides greater control over print settings and allows for advanced features like linear advance and mesh bed leveling. These options can significantly improve print quality and accuracy. Replacing the stock control board with a more advanced board can improve the overall performance and provide more processing power. Many modern control boards offer silent stepper motor drivers. They reduce noise and improve the print experience. Ensure you select a control board that is compatible with the Tevo Tarantula and that you have the necessary skills and knowledge for firmware flashing and board installation. Keep your firmware up to date and explore the numerous customization options. Updating these components can provide a better printing experience and greater control.

Silent Board Benefits

Silent stepper motor drivers are an essential upgrade for anyone seeking a quieter 3D printing experience. The stock drivers can be noisy and contribute to a distracting printing environment. Silent drivers significantly reduce the noise generated by the stepper motors, making the printer much quieter. This is especially beneficial if you print in an office or living space. Besides reducing noise, silent drivers can improve print quality by reducing vibrations. With less vibration, there is a reduction in the chances of printing defects such as ringing. Silent drivers are often integrated into a new control board or can be added to your existing board. This can lead to a smoother, quieter, and more enjoyable printing experience. The lower noise level makes it easier to monitor your prints and helps prevent fatigue. With the ease of installation and significant benefits, the silent board is one of the best upgrades you can add.

Improving Print Quality

Upgrading various components of your Tevo Tarantula can lead to improvements in print quality. Besides the direct benefits of each upgrade, there are several general strategies you can use to fine-tune your prints and achieve better results. Proper calibration of your printer is crucial for optimal print quality. Calibration involves ensuring the printer’s components are set up correctly. This includes bed leveling, extruder calibration, and temperature settings. Print settings, like layer height, print speed, and infill density, play a significant role in the quality of your prints. Experiment with different settings to find the optimal balance between speed and quality for your specific printing needs. Using high-quality filament is also essential for achieving great print results. The quality and type of filament you use can significantly impact the final result. By combining the upgrades, proper calibration, and careful selection of settings and materials, you can ensure high-quality prints.

Belt and Pulley Upgrades

The belts and pulleys in a 3D printer are responsible for the smooth and accurate movement of the print head and bed. Upgrading these components can improve print quality by reducing vibrations and improving the printer’s precision. Upgrading to GT2 belts and pulleys can provide better precision and durability compared to the stock components. GT2 belts are designed for optimal tooth engagement and can reduce slippage. This translates to greater accuracy and better print quality. Ensure that the belts are properly tensioned and that the pulleys are aligned correctly. Over-tightening can lead to wear and tear, so follow the manufacturer’s recommendations. The pulleys should be of good quality and provide smooth operation to improve print quality. Upgrade the belts and pulleys with the appropriate parts for the Tevo Tarantula, paying close attention to proper setup and alignment.

Optimizing Print Settings

Fine-tuning your print settings is crucial for getting the best results from your upgraded Tevo Tarantula. Experimenting with different settings is a great way to improve quality and discover what works best for your needs. Print speed and layer height are essential parameters. Lowering print speed, particularly for intricate details, can often improve print quality. Layer height affects the level of detail in your prints. Adjusting these settings can significantly impact the print quality. Also experiment with temperature settings for the hotend and the print bed. Temperature affects the melting of the filament and the adhesion of the first layer. Start with the manufacturer’s recommendations and adjust the settings incrementally until you find the optimal range. Infill density and pattern can affect the strength and appearance of the print. Adjusting these settings will allow you to customize the strength of your prints. The combination of hardware upgrades and fine-tuning the printing settings is the key to unlocking the full potential of your Tevo Tarantula.

Cooling Fan Upgrades

Proper cooling is essential for producing high-quality prints, especially when printing overhangs and small details. The stock cooling fan on the Tevo Tarantula can sometimes be insufficient, leading to issues like warping and poor overhangs. Upgrading the cooling fan will ensure that the layers of filament cool quickly and evenly, thereby improving print quality and the printer’s ability to handle challenging geometries. Consider upgrading to a high-performance fan with improved airflow. A part cooling fan directs air specifically at the printed part, while a hotend fan helps to cool the hotend. Proper cooling is essential for achieving high-quality prints. Ensure the fan is correctly oriented and that the airflow is directed towards the desired areas. When working with filaments like PLA that are particularly sensitive to heat, it’s even more crucial to ensure adequate cooling. You will get significantly better overhangs and overall print quality.

Improving Reliability and Safety

While upgrades can significantly improve your printer’s performance, it’s equally important to focus on reliability and safety. There are several upgrades you can consider to enhance the safety and reliability of your Tevo Tarantula. A reliable power supply is vital for the safety and performance of your printer. Upgrading the power supply can provide a more stable and safer power source, which is especially important for long print jobs. Consider upgrading to a power supply that has adequate capacity and is specifically designed for 3D printers. Another essential upgrade is the addition of a MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) for the heated bed. A MOSFET helps to regulate the power to the heated bed, reducing the risk of fire. Safety is a top priority when operating a 3D printer. Make sure your printer is positioned on a stable surface and is in a well-ventilated area. Regular maintenance and inspection of your printer will help ensure safe operation. By taking these steps, you can significantly improve the safety and reliability of your 3D printer.

Power Supply Upgrades

The power supply is a critical component that provides electricity to your 3D printer. Upgrading the power supply is one of the most important upgrades for ensuring safety and reliability. A quality power supply provides clean and stable power, which helps prevent print failures and protects other components from damage. Replacing the stock power supply with a reputable unit can significantly improve the printer’s performance and safety. Consider the power requirements of your printer and choose a power supply that meets or exceeds the required wattage. Ensure that the power supply has the necessary safety certifications and protections, such as over-current protection and over-voltage protection. When installing a new power supply, it is essential to carefully follow the wiring instructions and ensure that all connections are secure. A reliable power supply is the foundation of a safe and effective 3D printing experience, protecting your printer and your home from potential hazards. Prioritizing this upgrade will reduce the risk of print failures and prolong the life of your printer.

Enclosure Options for the Tevo Tarantula

An enclosure can provide numerous benefits for your Tevo Tarantula, enhancing the printing environment and overall print quality. An enclosure helps maintain a stable temperature, which is especially important when printing with materials like ABS or other filaments prone to warping. It can also help to contain odors and fumes, improving the air quality in your workspace. While you can purchase a pre-made enclosure, building your own enclosure can be a fun and cost-effective project. DIY enclosures can be customized to fit your specific needs and printing setup. When building an enclosure, consider materials like acrylic, wood, or even repurposed materials. Ensure the enclosure is properly ventilated to prevent heat buildup. An enclosure is an excellent way to improve the performance and safety of your Tevo Tarantula, particularly when working with temperature-sensitive or odor-emitting filaments. Consider this upgrade to safeguard your prints and improve your printing experience. This will also allow you to print more advanced filaments.