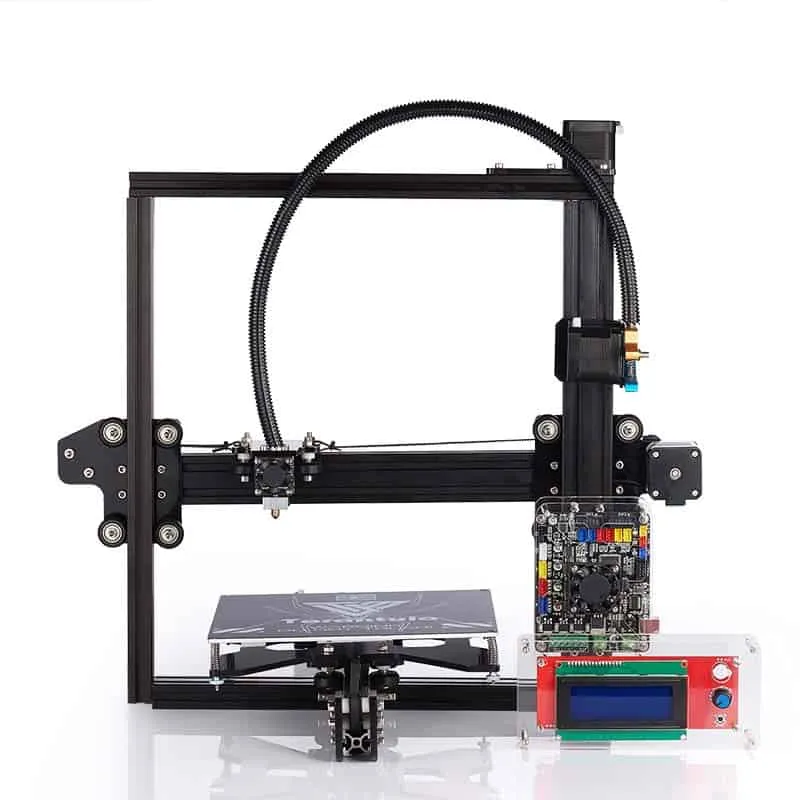

What is a Thermistor and Why Replace it?

In the realm of 3D printing, the thermistor is a tiny yet pivotal component. It functions as a temperature sensor, providing essential data to your 3D printer’s control board. This information is used to regulate the temperature of the hot end and the heated bed, enabling the precise melting and deposition of filament. Without an accurately functioning thermistor, your prints will suffer, leading to inconsistent layer adhesion, warping, and even complete print failures. Replacing a thermistor becomes necessary when it malfunctions, providing incorrect temperature readings, or failing altogether. This could be due to age, physical damage, or electrical issues. A faulty thermistor can lead to your printer misinterpreting the temperature, causing it to overheat or fail to reach the required printing temperatures, directly impacting print quality and the lifespan of other printer components.

Symptoms of a Faulty Thermistor

Recognizing the signs of a failing thermistor is key to addressing the issue promptly. Several symptoms can point towards thermistor trouble. One of the most common indicators is erratic temperature readings. The temperature on the printer’s display might fluctuate wildly, or the printer may report an error message like “ERR TEMP”. Another sign is inconsistent heating. The hot end or the heated bed might take an unusually long time to heat up, or they might not reach the set temperature at all. Other issues include prints that don’t adhere to the bed properly, leading to warping or lifting. If you notice these symptoms, it’s highly likely that your thermistor requires replacement. Ignoring these signs could lead to further damage to your 3D printer and negatively impact your printing results. Regular monitoring and awareness of these symptoms can help you prevent major print failures and maintain the optimal performance of your Tevo Tarantula.

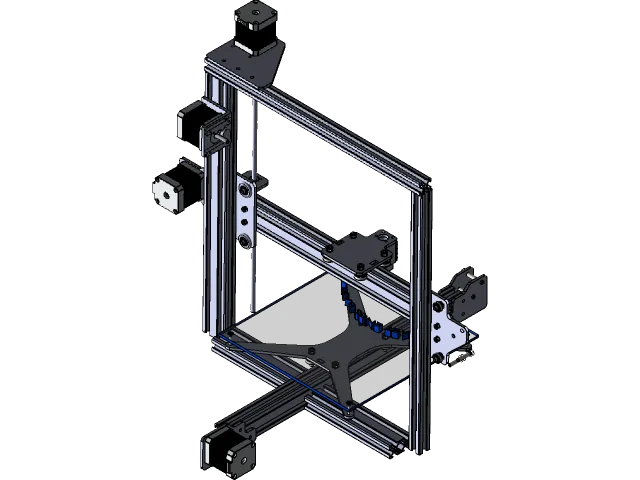

Preparing for the Tevo Tarantula Thermistor Replacement

Before you begin the thermistor replacement process, proper preparation is paramount. Safety should be your top priority. Start by unplugging the 3D printer from the power source and allowing ample time for the hot end and heated bed to cool down completely. This prevents accidental burns and ensures a safe working environment. Next, gather all the necessary tools and materials, including a replacement thermistor that is compatible with your Tevo Tarantula model. Consult your printer’s manual or the manufacturer’s website for the correct specifications. Set up your workspace in a well-lit area to improve visibility and allow for comfortable access to the printer. Take photos of the existing wiring setup before you disconnect anything, this can be a valuable reference during reassembly. Lastly, clear your work area to prevent losing any small parts or tools during the replacement.

Tools and Materials Needed

Having the right tools and materials at your disposal is essential for a smooth and successful thermistor replacement. You’ll need a replacement thermistor specifically designed for your Tevo Tarantula 3D printer; check the specifications to ensure compatibility. A set of small screwdrivers, including Phillips head and possibly flathead, will be required for disassembling and reassembling the hot end assembly. Wire strippers and crimpers can be useful if you need to cut or reconnect the thermistor wires, though this depends on the thermistor type. A multimeter can also prove invaluable to test the old thermistor for continuity and verify the new one’s functionality. A pair of pliers can aid in removing and installing the thermistor. Finally, a small container or tray is recommended to hold the screws and small parts, preventing them from getting lost. Having these tools organized and readily available will significantly streamline the replacement process.

Step-by-Step Thermistor Replacement Guide

Step 1 Disconnect Power and Cool Down

Safety first is the golden rule. Begin the process by unplugging your Tevo Tarantula 3D printer from the electrical outlet. Ensure the power is completely off to eliminate any risk of electrical shock. Next, allow ample time for the hot end and the heated bed to cool down. This could take a while, so be patient. Touching a hot hot end or bed can result in severe burns. Verify the temperature of the hot end using the printer’s display if available, or gently touch the nozzle and bed (carefully) to ensure they are safe to handle before proceeding to the next steps. Only proceed with the replacement when the printer is completely cool and the power is disconnected.

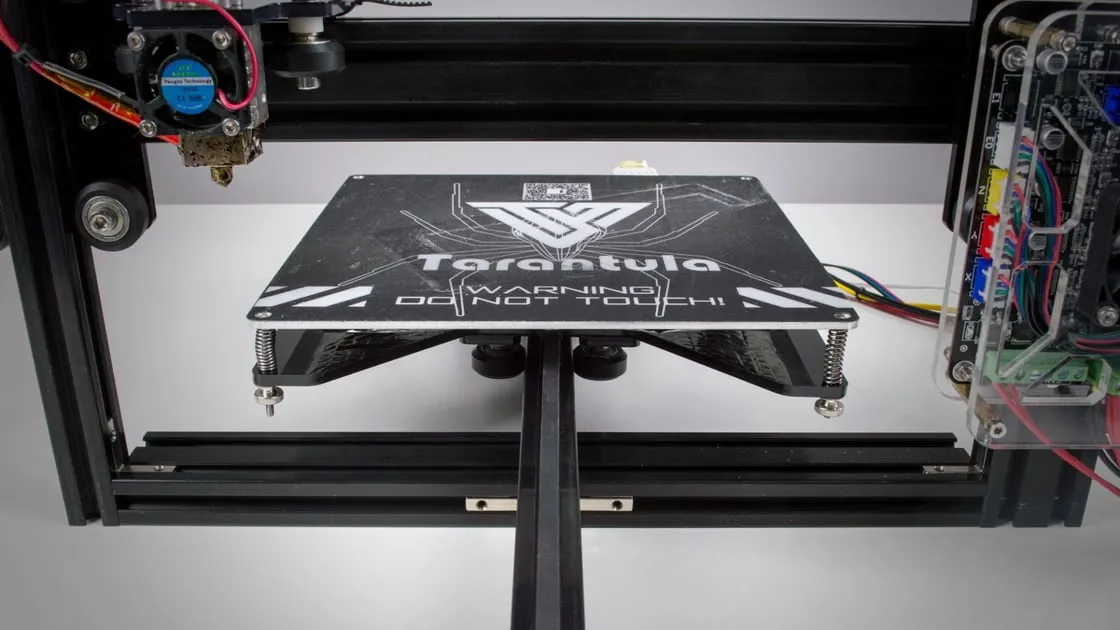

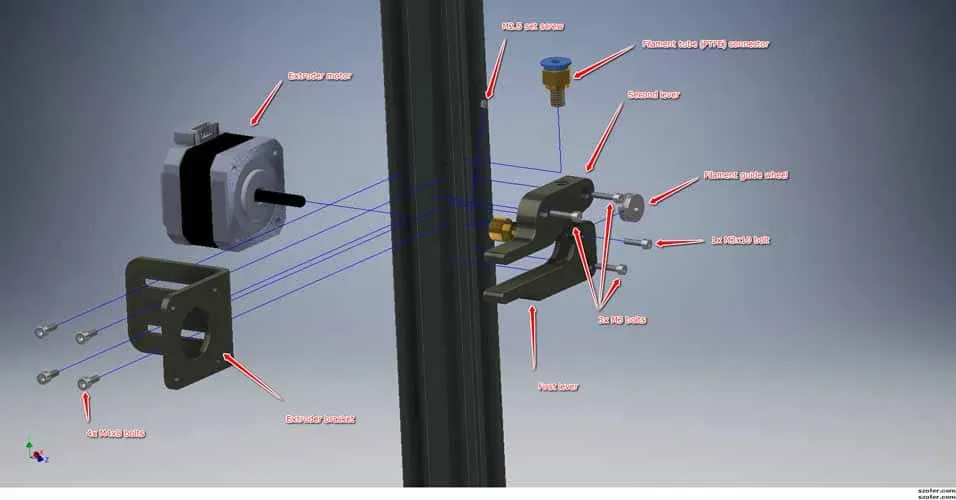

Step 2 Access the Thermistor

Carefully disassemble the hot end assembly to access the thermistor. This may involve removing the cooling fan shroud, the silicone sock, and possibly the nozzle. The specific steps will depend on your particular Tevo Tarantula model. Consult the printer’s manual or online guides if needed. Once you’ve removed the necessary components, you should be able to see the thermistor, which is usually a small cylindrical or bead-shaped component. Take note of how the thermistor is mounted and wired, as this will be important for reassembly. It’s often secured with a screw or held in place by the heater block. Documenting the existing setup with photos can be a great help at this stage.

Step 3 Remove the Old Thermistor

Now, carefully remove the old thermistor. If it’s held in place by a screw, loosen the screw and gently pull the thermistor out. Be careful not to damage the heater block or the wiring. If the thermistor is held in place by other means, carefully assess how to remove it without causing any harm. Disconnect the thermistor wires from the control board. Before disconnecting, make sure to take note of how the wires were connected, in case they aren’t labeled. You can mark them or take a picture for reference. Once removed, inspect the thermistor for any visible damage. If the thermistor wires are damaged, you may need to crimp or solder them. Ensure that the connections are secure before proceeding.

Step 4 Install the New Thermistor

Install the new thermistor in the same way the old one was mounted. Make sure it’s securely held in place and makes good contact with the heater block. This ensures accurate temperature readings. If the thermistor is secured by a screw, tighten the screw carefully, taking care not to overtighten it. Connect the thermistor wires to the control board, following the same connections as the old thermistor. Double-check the connections to ensure they are secure and properly aligned. After installing, verify that the wires aren’t touching any moving parts or sources of heat. This can prevent premature failure of the thermistor. It is critical that the connections are made properly to enable correct temperature readings.

Step 5 Reassemble and Test

Carefully reassemble all the components you removed in the previous steps, including the cooling fan shroud, the silicone sock, and any other parts you took apart. Make sure everything is securely in place. After reassembly, plug the 3D printer back into the power outlet and turn it on. Heat up the hot end to the usual printing temperature and monitor the temperature readings on the printer’s display. The readings should be stable and within the expected range. If the temperature readings seem normal, start a small test print to further verify that the thermistor replacement was successful. The test print can identify any remaining issues with the process. Observe the first layer adhesion and the print quality to ensure the thermistor is functioning correctly.

Troubleshooting Common Issues

Even with careful execution, you might encounter some issues. One common problem is the printer not heating up. This could be due to a faulty connection or a problem with the heater cartridge. Double-check all the wiring connections to ensure they are secure. Another issue is inaccurate temperature readings. In this case, make sure the thermistor is making good contact with the heater block and that the correct thermistor type is selected in the printer’s firmware. If the readings are off, you may also need to calibrate the thermistor. If you experience print quality issues, examine the first layer adhesion. If the filament doesn’t stick properly, the nozzle may not be at the correct temperature. Addressing these issues promptly will help to avoid further complications and achieve successful prints.

Calibrating the Thermistor After Replacement

After replacing the thermistor, it’s crucial to calibrate it to ensure accurate temperature readings. This process usually involves adjusting the thermistor’s settings in the printer’s firmware. This ensures that the printer accurately reads the temperature, which is essential for good print results. To calibrate, you will need to access the firmware settings, which varies depending on your 3D printer’s control board. Common firmware platforms include Marlin and Repetier. The calibration process typically involves entering the thermistor’s beta value, or you can use a temperature probe to check the actual temperature of the hot end. Match the temperature on the printer’s display to the value measured by the temperature probe. After calibration, test the settings with a test print to confirm the outcome.

Maintaining Your 3D Printer for Optimal Performance

Proper maintenance is essential for keeping your 3D printer running at its best. Regularly inspect the thermistor and other components for signs of wear or damage. Clean the hot end and nozzle to prevent filament buildup that can affect print quality and temperature readings. Check and tighten any loose screws, belts, or other moving parts. Keep your printer clean from dust and debris, which can interfere with its operation. Lubricate moving parts as recommended in your printer’s manual. Regularly update your printer’s firmware to take advantage of performance improvements and bug fixes. By following these maintenance tips, you can extend the life of your 3D printer and enjoy reliable printing results for many years to come.