What is the Tevo Tarantula Prusa

The Tevo Tarantula Prusa is a popular and affordable 3D printer, often favored by beginners due to its relatively easy assembly and active community support. It’s based on the Prusa i3 design, known for its open-source nature and adaptability. This means users can modify and upgrade the printer to their specific needs, making it a great choice for those who want to learn about 3D printing and tinker with their machine. The Tevo Tarantula offers a decent build volume and can print with various filaments, providing a versatile platform for various projects. It’s a gateway into the world of 3D printing, providing a balance between affordability, functionality, and the ability to learn and experiment.

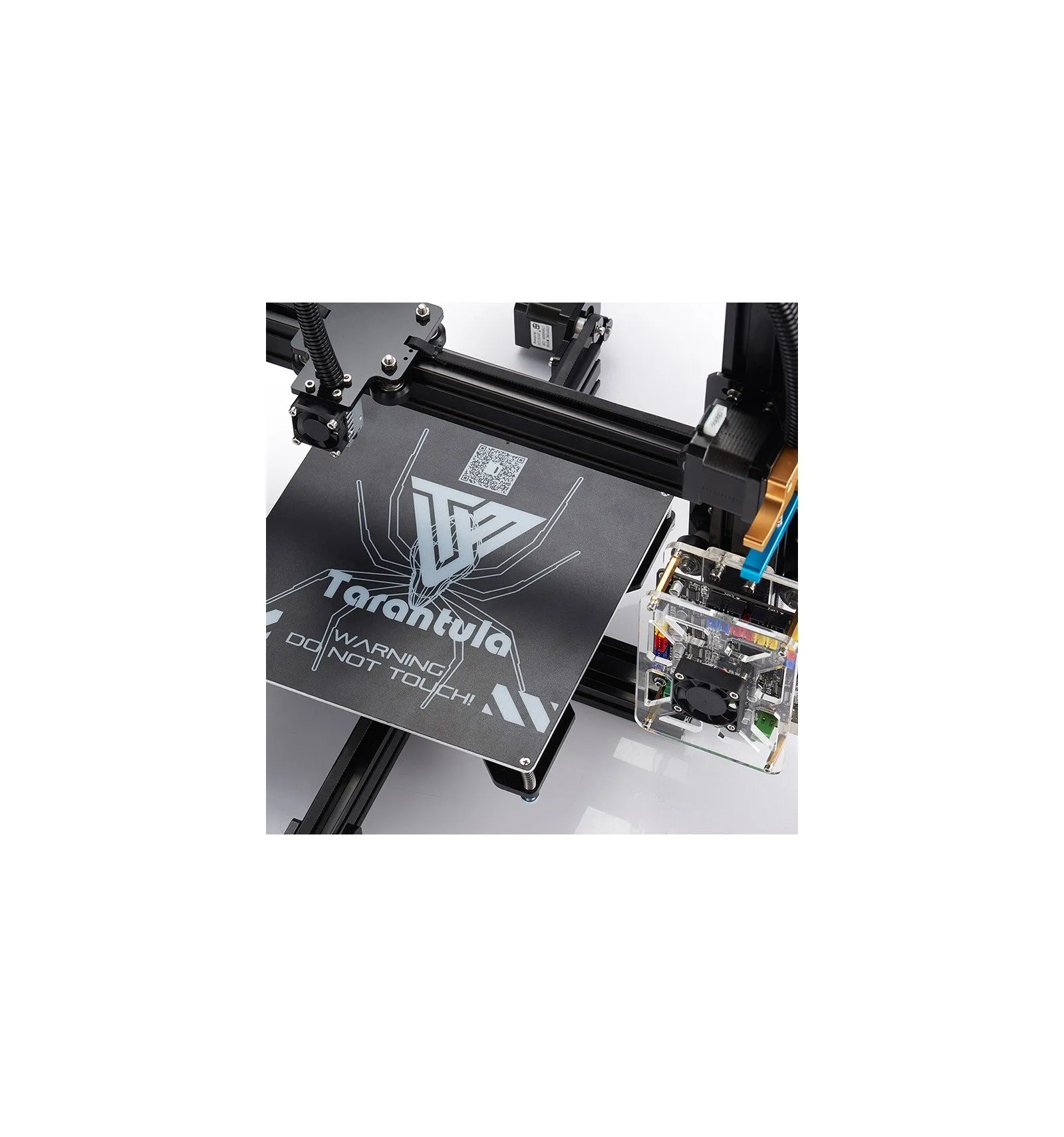

Key Features of the Tevo Tarantula Prusa

The Tevo Tarantula Prusa boasts several features that make it appealing to beginners. It typically includes a heated bed, essential for printing with materials like ABS and PETG, which require a consistent temperature to adhere properly. It usually has a decent build volume, allowing for the creation of moderately sized objects. The printer often features an LCD screen and control knob for easy navigation and control of printing parameters. It has a sturdy frame, which is crucial for stable printing. The open-source nature of the design allows for modifications and upgrades, so the printer can evolve with the user’s skills. These features work together to create a functional and adaptable 3D printer.

Assembly Guide for Tevo Tarantula Prusa

Assembling your Tevo Tarantula Prusa is a significant step toward getting your printer up and running. While it may seem daunting at first, following a well-structured guide can make the process manageable. The assembly usually involves attaching various components to the frame, connecting the electronics, and ensuring everything is aligned correctly. Clear instructions are usually provided, but online video tutorials are a great additional resource. Taking your time during assembly and double-checking connections is crucial to ensure the printer functions correctly. Proper assembly sets the foundation for successful 3D printing and optimal performance. Make sure to have a dedicated workspace where you can spread out and work comfortably.

Step-by-Step Assembly Process

The assembly process generally begins with attaching the frame components, ensuring they are square and stable. Next, the heated bed and its supports are attached, followed by the X, Y, and Z-axis components. Then, the extruder, stepper motors, and endstops need to be installed. Wiring the electronics, including the power supply, control board, and display, is a crucial step. It’s essential to carefully follow the wiring diagrams to avoid any electrical issues. Finally, the belts and pulleys need to be installed and tensioned correctly, ensuring smooth movement. The step-by-step process, with clear instructions, makes the assembly process more achievable. Regular checks and double-checking are critical.

Tools and Materials Needed

The necessary tools and materials usually come included with the Tevo Tarantula Prusa kit, but it’s always a good idea to have a few extra items handy. A set of Allen wrenches (metric) is essential for tightening screws. A screwdriver set is important for different types of screws. A pair of pliers is helpful for managing wires and cutting filament. A digital caliper can be used to ensure precise measurements of parts. Electrical tape can be helpful for securing wires, and zip ties can keep cables organized. Also, it can be handy to have a level for bed calibration and filament clippers. Having these tools readily available will streamline the assembly process. This way, you won’t need to stop to search for a missing tool.

Calibrating Your Tevo Tarantula Prusa

Calibration is essential for a successful 3D printing experience. The process ensures that the printer is set up correctly, so it can produce accurate and high-quality prints. Calibration involves several steps, including bed leveling, Z-axis calibration, and adjusting other settings in your printer’s firmware. It’s usually done after assembly and whenever you make changes to the printer’s hardware. Proper calibration prevents common issues such as poor bed adhesion, nozzle dragging, and incorrect layer heights. By taking the time to calibrate your Tevo Tarantula Prusa, you’ll be setting the stage for a better printing experience. Regular calibration also helps to maintain print quality over time.

Bed Leveling Techniques

Bed leveling is one of the most critical steps in the calibration process. The goal is to ensure the distance between the nozzle and the print bed is consistent across the entire surface. You can manually level the bed using the adjustment screws or, if your printer has it, use an auto-leveling system. Manual bed leveling involves adjusting the screws at each corner of the bed until the nozzle is the correct distance from the bed surface. Paper is often used to help with the process. Auto-leveling systems use sensors to measure the distance from the nozzle to the bed. There are numerous online guides and videos that make bed leveling easy to understand.

Z-Axis Calibration

Z-axis calibration ensures the nozzle is the correct distance from the bed. The Z-axis offset is the distance the nozzle moves from its home position to the bed. This setting is often configured in your printer’s firmware or through the printer’s control panel. The proper Z-offset setting is essential for the first layer of a print to adhere correctly to the bed without the nozzle dragging. You can find this setting by carefully adjusting the Z-offset until the first layer looks right, with good adhesion and no gaps between the lines. Using a test print, like a single-layer square, helps to determine the ideal Z-offset setting.

First Print Setup

Before you print your first model, there are a few things you need to do. You will need to choose a suitable filament, and then select and download a 3D model. Also, you’ll need to use slicing software to convert the 3D model into instructions that the printer can understand (G-code). Be sure to calibrate the printer as described above. This will make your first print successful. Be patient and take your time when setting everything up; you’ll be glad you did. Many online tutorials exist for the printing process. A little bit of preparation will go a long way.

Choosing the Right Filament

Choosing the correct filament is important for successful prints. The most common filament is PLA (Polylactic Acid), which is easy to use, has low warping, and is suitable for beginners. ABS (Acrylonitrile Butadiene Styrene) is another common option, offering greater strength and temperature resistance but may require a heated bed and enclosure. PETG (Polyethylene Terephthalate Glycol) offers a balance between strength, flexibility, and ease of printing. Other options include flexible filaments, such as TPU, and specialized filaments like nylon and carbon fiber composites. Research different filament properties to choose the right one for your project. Consider the mechanical properties and printing requirements of each type. PLA is a great starting point.

Slicing Software Basics

Slicing software converts your 3D model into instructions for the printer. The software slices the 3D model into thin layers and generates G-code, which the printer uses to control the movement of the nozzle and the extrusion of filament. Popular slicing software options include Cura, PrusaSlicer, and Simplify3D. In the slicing software, you can configure print settings like layer height, infill, print speed, and temperature. Experimenting with different settings will allow you to optimize print quality and speed. Following some basic settings for your filament and printer can get you a successful print in no time.

Printing Your First Model

Once you’ve set up your slicer and have your printer ready, you’re ready to print your first model. Load the G-code file onto the printer, either via SD card or a direct connection. Preheat the nozzle and bed to the recommended temperatures for your filament. Monitor the first layer closely to ensure proper adhesion and that the nozzle is at the correct height. If you find any issues, you can usually adjust the bed leveling or Z-offset mid-print. Once the first layer is down, your printer should start printing your model. Then, it’s a matter of watching the machine do its work and waiting for the final product to be created. The first print will be an exciting moment.

Troubleshooting Common Issues

Even with careful preparation, you may encounter issues while 3D printing. Learning to identify and resolve common problems is an essential part of the 3D printing experience. Common issues include nozzle clogs, bed adhesion problems, layer shifting, and more. Several online resources, including forums and communities, can help you troubleshoot these issues. There are also many videos online that make troubleshooting much easier. It will take some time to become proficient at troubleshooting, but that is part of the fun and rewarding experience of 3D printing.

Nozzle Clogging

Nozzle clogs are a common issue. They can happen due to a variety of factors, including incorrect temperature settings, dust or debris in the filament, or a degraded nozzle. If you experience a clog, first try increasing the nozzle temperature to see if that helps. You can also try using a cleaning needle to clear the clog. Another option is a cold pull, which involves heating the nozzle, manually extruding filament, and then cooling it. The cooled filament can be pulled out, hopefully taking the clog with it. Regular maintenance can help prevent clogs, such as by keeping your filament dry.

Bed Adhesion Problems

Bed adhesion problems result in the print not sticking to the bed. Several factors can contribute to this, including an improperly leveled bed, incorrect nozzle height, or a dirty bed surface. Ensure your bed is properly leveled and the nozzle is at the correct height relative to the bed. Clean the bed surface with isopropyl alcohol to remove any residue that might affect adhesion. You can also use adhesives like glue sticks, hairspray, or blue painter’s tape to improve adhesion. Adjusting the bed temperature can also improve adhesion.

Layer Shifting

Layer shifting is when the layers of your print do not align correctly, resulting in a distorted model. This can occur due to various reasons, including loose belts, stepper motor issues, or the printer’s speed being set too high. Make sure the belts on your printer are tight and properly tensioned. Check the set screws on the pulleys to ensure they are secure. Reduce the printing speed and acceleration settings to prevent the motors from skipping steps. If the problem persists, you may have an issue with your stepper motors, which might require some maintenance.

Maintenance and Upgrades

Regular maintenance and upgrades will help extend the life of your Tevo Tarantula Prusa and improve its performance. Taking care of your printer will save you money and help to maintain print quality. These actions are also part of the enjoyment of the hobby. From cleaning to upgrades, the Tevo Tarantula Prusa can evolve as your skills grow. Be sure to find what works best for you and your specific needs.

Regular Maintenance Tips

Several regular maintenance steps are important for keeping your printer in good shape. Clean the print bed regularly to remove residue. Clean the nozzle to remove any filament build-up and prevent clogs. Lubricate moving parts, such as the Z-axis rods, to keep the movement smooth. Check the belts to make sure they are tight and properly tensioned. Inspect and tighten the screws on your printer to maintain its structural integrity. Keeping your printer clean and well-maintained will extend its lifespan and will help you get the best prints.

Upgrading Your Tevo Tarantula Prusa

The Tevo Tarantula Prusa is a highly adaptable machine. Numerous upgrades are available to enhance its performance. Upgrades can improve print quality and speed. Consider upgrades like a glass bed for improved bed adhesion and flatness. You can upgrade to a new extruder and hotend for more reliable filament feeding and higher printing temperatures. You can also upgrade the control board to add advanced features. Upgrading your printer allows you to customize it to fit your needs and improve your 3D printing experience. Online communities offer plenty of resources for upgrades.